MBR1650

Product Overview

Category

The MBR1650 belongs to the category of Schottky Barrier Rectifiers.

Use

It is used as a rectifier in various electronic circuits and power supply units.

Characteristics

- High current capability

- Low forward voltage drop

- Fast switching speed

- High temperature operation

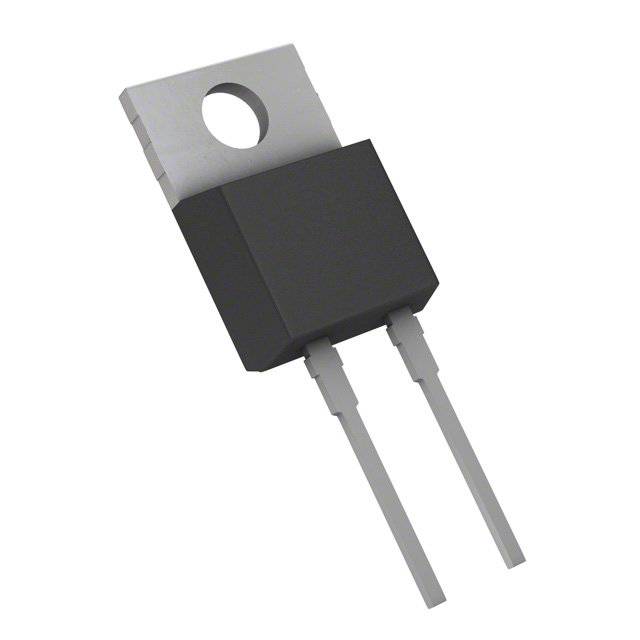

Package

The MBR1650 is typically available in a TO-220AB package.

Essence

The essence of the MBR1650 lies in its efficient rectification capabilities and high reliability.

Packaging/Quantity

It is commonly packaged in reels or tubes, with quantities varying based on manufacturer specifications.

Specifications

- Maximum Average Forward Current: 16A

- Peak Forward Surge Current: 150A

- Reverse Voltage: 50V

- Operating Temperature Range: -65°C to +175°C

- Storage Temperature Range: -65°C to +175°C

Detailed Pin Configuration

The MBR1650 has a standard pin configuration with the following pins: 1. Anode 2. Cathode

Functional Features

- Low power loss and high efficiency

- Guard ring for enhanced ruggedness and long-term reliability

- Lead (Pb)-free construction

Advantages and Disadvantages

Advantages

- High current carrying capability

- Fast switching speed

- Low forward voltage drop

Disadvantages

- Limited reverse voltage rating compared to some alternative models

- Relatively higher cost compared to standard diodes

Working Principles

The MBR1650 operates based on the Schottky barrier principle, where the metal-semiconductor junction allows for faster switching and lower forward voltage drop compared to conventional PN-junction diodes.

Detailed Application Field Plans

The MBR1650 finds extensive use in the following applications: - Switching power supplies - DC-DC converters - Reverse polarity protection circuits - Battery charging circuits

Detailed and Complete Alternative Models

Some alternative models to the MBR1650 include: - MBR1645 - MBR1660 - MBR1660CT

In conclusion, the MBR1650 is a reliable and efficient Schottky Barrier Rectifier that finds widespread application in various electronic circuits and power supply units due to its high current capability, low forward voltage drop, and fast switching speed.

[Word count: 314]

Senaraikan 10 soalan dan jawapan biasa yang berkaitan dengan aplikasi MBR1650 dalam penyelesaian teknikal

What is MBR1650?

- MBR1650 is a type of Membrane Bioreactor (MBR) system used for wastewater treatment, combining activated sludge process with membrane filtration.

How does MBR1650 work?

- MBR1650 works by using a combination of biological treatment and membrane filtration to effectively remove contaminants from wastewater, producing high-quality treated water.

What are the key advantages of using MBR1650 in wastewater treatment?

- Some key advantages include smaller footprint, higher effluent quality, reduced sludge production, and better resistance to fluctuations in influent characteristics.

What are the typical applications of MBR1650?

- MBR1650 is commonly used in municipal wastewater treatment plants, industrial wastewater treatment, decentralized wastewater treatment systems, and water reuse applications.

What maintenance is required for MBR1650 systems?

- Regular maintenance includes membrane cleaning, inspection of aeration equipment, monitoring of biological activity, and periodic sludge removal.

What are the potential challenges associated with MBR1650 systems?

- Challenges may include membrane fouling, high energy consumption, initial capital costs, and the need for specialized expertise in operation and maintenance.

Can MBR1650 be integrated with other treatment processes?

- Yes, MBR1650 can be integrated with additional treatment processes such as UV disinfection, advanced oxidation, or tertiary filtration to meet specific effluent requirements.

What are the key design considerations for implementing MBR1650 in a new project?

- Design considerations include hydraulic retention time, membrane module selection, aeration system design, control strategies, and provision for future expansion.

Are there any specific regulations or standards that govern the use of MBR1650 systems?

- Compliance with local, national, and international regulations related to wastewater treatment, effluent discharge, and water reuse should be considered when implementing MBR1650.

What are the typical operational costs associated with running MBR1650 systems?

- Operational costs include energy consumption, membrane replacement, chemical usage, labor, and disposal of waste sludge. Proper cost analysis and budgeting are essential for long-term sustainability.